TSG-2 WHOLE VACUUM TRANSFER HIGH SPPED PRINTER SLOTTER DIE CUTTER MACHINE

Product Details

◆全程吸风设计,高清满版印刷

◆前缘吸附送纸,风量可调,主机变频控制。

◆PLC 电脑相位电动调整,各连接部气动锁定,电动分合,◆精磨齿轮,齿轮润滑采用喷淋式循环润滑,免键结构锁紧,

◆套色准确,印刷图案精美。◆使用和维修方便,自动化程度较高、高效率生产等。

Performance Characteristics of The Whole Machine

◆The whole process of vacuum suction design,full version printing with high definition.

◆Lead-edge suction feeding system,adjustable air volume,frequency convertor main motor.

◆Phase electric adjustment by PLC , connection unit locking by pneumatic,electrically control the separation and combination of machine.

◆Well grinded gear with spray lubrication system, Gears adopt keyless connection.

◆Chromatically multicolor printing accurately , printing effect beautiful.

◆Easy operation and convenient maintenance,high degree of automation,high degree of automation,high effciency production.

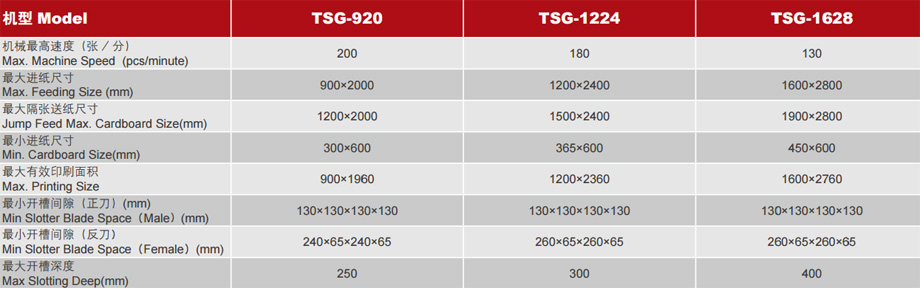

技术参数 (SPECIFCATIONS)

◆可连续或隔张送纸(有计数器)。

◆三轴前缘送纸,加大风机流量,送纸更平稳准确。

◆变频控制真空气流和压力,以配合纸板尺寸。

◆可调整送纸行程,减轻拉纸胶辊压力。

◆拉纸胶辊间隙,左右挡纸板位置,电脑控制调整。

◆后托纸架电脑控制前后,加快设置速度。

◆静电除尘装置,多排毛刷及风机清除纸板表面纸屑,提高印刷品质。

◆送纸辊钢辊表面冼直线,再镀硬铬。

◆送纸压力辊间隙调整采用电脑控制,控制范围 0-12mm。

◆压力辊的动力传动采用凸轮轴承传动,减少磨损使传动更平稳。

◆主机马达启动保护装置。

◆送纸单元、印刷单元采用编码器自动归零。

◆一般纸箱使用自动归零装置,试印二张即可调整至正确位置,减少纸板浪费。

Feeder Unit

◆Can be continuous feeding and space feeding.

◆Three rollers feeding,increase fan flow,feeding stably and accurately.

◆Inverter control the vacuum air and presure,to follow the cardboard size.

◆Can adjust the feeding proceding to reduce the presure of feeder roller.

◆Computer control the space of feeder roller and the position of both sides guard.

◆Backside stacker computer control front and backside,increse the speed of set up.

◆Electrostatic dust removing device,Multi brush and fan cleanning the wastepaper in surface of the cardboard.To increase the printing quality.

◆The roller are made by steel with hard chrome plating.

◆The adjustment of presure of feeder rollers adopts computure control,between 0-12mm.

◆The power transmission system adopts cam bearing transmission,in order to reduce the abrasion and make the transmission more steady.

◆Protector of main motor start(The main motor can not start when the machine didn't lock well).

◆Feeder Unit and Printer Unit adopt encoder making zero.

◆Ordinary carton producing can use making zero automatic device.The correct position can be adjusted by test printing of 2 cardboards.In order to not waste cardboard.

真空传送印刷单元

◆印刷辊为优质钢,表面研磨,镀硬铬。

◆平衡校正,运转平稳。

◆卷轴挂版,采用左右两边锁紧装置,使挂版对位准确。

◆全版挂版沟,适用 10mm×3mm 挂版条。

◆装卸印刷板,脚踏开关电动控制正反转。

◆采用真空吸附输送纸板 ( 送纸轮表面为陶瓷、增加耐磨及寿命 )。不必使用拉纸环就可以使纸板通过印刷部。

◆压印辊间隙调整采用电脑及电子数字式控制,控制范围 0-12mm。

◆印刷相位调整采用伺服电机驱动。

◆印刷相位固定装置,电磁离合器制动式刹车机构。当单元分离调整相位或清洗时,刹车机构限制齿轮转动,保持原有齿轮位置固定点。

◆横向相位采用电脑控制,控制范围 ±10mm。

◆清洗印版后自动复位系统。

◆气压式单隔膜泵,供墨稳定,操作保养简单。

◆供墨异常,警示灯显示。

◆滤网过滤墨中杂质,保护网纹辊。

◆腔刮刀供墨系统下配有墨槽。

◆自动切换清洗装置,让水墨回收更彻底。

Vacuum Transfer Printing Unit

◆The printing rollers are rollers are made by high quality steel, hard chrome plating,surface grinding.

◆Balance correction make the machine running more steadily.

◆Scroll hanging the printing sheet,adopt lock device by both sides.Make the sheet in correct regestration.

◆Full sheet hanging channel,Fit for 10mm×3mm hanging bar.

◆Pedal switch control the printing roller turning forward or back off when install the printing sheet.

◆Adopts vacuum transfer(The surface of the transfer wheel is made by ceramic,in order to increase the rub and using life).Can transfer the cardboard without transfer roller.

◆The adjustment of the Printing presure rollers space adopts computure control,between 0-12mm.

◆Servo motor is adopted for phose adjustment.

◆Immobilization device of the printing phose.Electromagnetic clutch brake type brake mechanism.The Brake mechanism to limit gear rotation,Maintain the fixed position of the original gear when the units seperate or adjust the phose and cleaning.

◆Horizontal phase using computer control,±10mm.

◆Automatic reset system after cleaning plate.

◆Pneumatic single diaphragm pump,Ink supply stability,Operationand maintenance is simple.

◆Warning light displays when Ink supply anomaly .

◆The rosebox filters the impurity substance of the ink,to protect the anilox.

◆Ink tank is placed under the Single blade ink supply system.

◆Automatic switching cleaning device makes ink recycling more thorough.

开槽单元

◆压线轴和开槽刀轴均为为实心钢,研磨加工,表面镀硬铬。

◆第一压线轮,经预压线后的纸板不易压破。

◆上压线轮外表包裹优力胶,不损坏纸板。

◆压线及预压轮调整间隙采用电脑及电动数字式控制。

◆开槽刀轴间隙采用电动调整,调整范围 0-12mm。

◆压力辊的动力传动采用凸轮轴承传动,减少磨损使传动更平稳。

◆上刀座与下刀座采用传动轴联动,移动时保持上下刀对准,延长刀具寿命。

◆预压轮、压线轮、开槽刀座横移位置,采用电脑及电动数字控制。

◆开槽刀箱高调整有防碰撞保护装置,不会损坏机器。

◆弹性切角刀结构,可切断三层、五层纸板无需调整,操作方便。

Slotter Unit

◆Creaser axis and Slotter axis adopt solid steel,hard chrome plating,surface grinding.

◆The cardboard is not easy to be broken after creased by the first creaser wheel.

◆The upper creaser wheel is wrapped with rubber,avoid to damage the cardboard.

◆Computure and digit control systerm are dopted for the space of creasers.

◆Motor control is adopted for the space of slotter axis.

◆The power transmission system adopts cam bearing transmission,in order to reduce the abrasion and make the transmission more steady.

◆Drive shaft linkage is adopted for upper blades traverse and nether blades traverse.

◆Computure and digit control systerm are dopted for the traverse adjustment of creaser wheel and slotter blade.

◆Collision protect device is adopted for slotter blade height,avoid to damage the machine.

◆Elastic corner cutting blade structure,can cut 3 layers ans 5 layers cardboard without adjustment,easy operation.

干燥单元

◆真空吸附滚轮传送,滚轮多排错位排列,加强纸板传输稳定。

◆风箱风门可根据纸板大中小规格,进行自动调整。

◆可根据配置选用热风 / 红外线 /IR/ 紫外线 UV 三种干燥系统。

◆干燥系统采用 PLC 程序自动控制。

◆温控自动化控制,故障报警保护。自动检测报警和故障状态显示。

◆烘干系统随主机双重保护控制启动和闭合,完全解决印刷产品因停机时 UV/IR 灯直接照射时间过长而受热燃烧或损伤印刷品。

DRYER UNIT

◆Vacuum adsorption roller transfer, roller rows of staggered arrangement, to strengthen the stability of the board transfer .

◆The air door can be adjusted automatically according to the cardboard different size.

◆Can make selection of hot air / infrared /IR/ UV three kinds of drying system based on the configuration.

◆The drying system adopts PLC program automatic control.

◆Automatic control of temperature control, fault alarm protection, automatic alarm and fault status display.

◆Drying system adopts host dual protection control start and close.Completely solve the combustion and damage problem of the printing products,because of UV/IR lamp direct irradiation too long time when the machine stop working.

模切单元

◆刀模辊为优质钢,表面研磨,镀硬铬。

◆平衡校正,增加运转稳定性。

◆胶垫辊为优质钢,表面研磨,镀硬铬。

◆平衡校正,增加运转稳定性。

◆导纸辊间隙采用电脑及电动数字式控制。

◆行星齿轮式构造。

◆模切相位采用电脑及电动数字控制 360 度调整(运转、停止均可调整)。

◆横向相位采用电脑及电动数字控制,控制范围 ±10mm。

◆胶垫辊补偿采用伺服补偿驱动,控制胶垫辊筒的速度,补偿范围 ±3mm。

Die cutter Unit

◆The die roller is made by high quality steel, hard chrome plating,surface grinding.

◆Balance correction,Increase running stability .

◆The rubber roller is made by high quality steel, hard chrome plating,surface grinding.

◆Balance correction,Increase running stability .

◆Computure and digit control systerm are dopted for the space of transfer roller.

◆Planetary gear structure.

◆Computure and digit control systerm are dopted for the die cutting phose,can adjust circle.

◆Computure and digit control systerm are dopted for the broadwise phose by ±10mm.

◆Rubber pad roller compensation adopts servo motor,to control the speed of the rubber roller.Compensation range ±3mm.

© GuangZhou TaiSheng Carton Machinery Co.,Ltd