TSV-2 LEAD EDGE HIGH SPEED ROLLER TRANSFER PRINTER SLOTTER DIE CUTTER MACHINE

Product Details

整机功能介绍

◆该产品能一次性完成纸板的多色印刷、分切、压线、修边、开槽、切角、模切等多道工序。

◆前缘吸附送纸, 风量可调,主机变频控制。

◆PLC 电脑相位电动调整,各连接部气动锁定,电动分合。

◆精磨齿轮,齿轮润滑采用喷淋式循环润滑,免键结构锁紧。

◆套色准确,印刷图案精美。

◆使用和维修方便,自动化程度较高、高效率生产等。

Performance Characteristics of The Whole Machine

◆The product can complete the board multi-color printing, slitting indentation,trimming, slotting, corner cutting, die-cutting ,drilling and other programs ect.

◆Lead-edge suction feeding system,adjustable air volume,frequency convertor main motor.

◆Electric phase adjustment by PLC , connection unit locked by pneumatic,electrically control the separation and combination of machine.

◆Well grinded gear with spray lubrication system, Gears adopt keyless connection.

◆Chromatically multicolor printing accurately , printing effect beautiful.

◆Easy operation and convenient maintenance,high degree of automation,high effciency production.

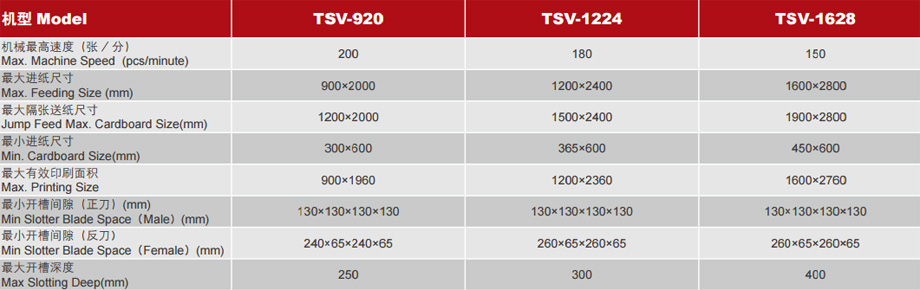

技术参数 (SPECIFCATIONS)

◆吸附风机辅助前缘定位自动送纸。

◆前缘送纸系统采用台湾技术。

◆前挡板电动调整、刻度盘显示。

◆侧挡板、后挡板电动调整。

◆配有自动除尘机构,有效清除纸板表面杂质。

◆隔张送纸功能,可根据需要选择连续或隔张送纸。

Feeder Unit

◆Absorption blower assist ahead orientation and automatic sending carboard.

◆The lead edge paper feeding system adopts Taiwan technology.

◆Front baffle manual adjustment,dial showing.

◆Equipment with brush to sufficiently eliminate dust automatically and scraps as well as foreigh substance.

◆Skip feed device with continuous feed or every other page feed options.

印刷单元

◆标配金属钢制网纹辊。(可选陶瓷网辊)。

◆配有快速挂版装置,装卸印刷版方便快捷。

◆印刷相位调整,采用 PLC、触摸屏控制,数字式 360 度正反转调整。

◆相位机构采用行星齿轮构造,使用寿命长。

◆配有自动刹车装置,当机台分离或调整相位时,限制机台转动,确保有齿轮位置固定不变。

◆选配印刷清洗后自动复位系统。

◆配有网纹辊自动抬升装置,停止送纸时网纹辊上升与印版分离。

◆所有电器采用进口施耐德电器。

◆电机采用台湾产的减速马达。

Printing Unit

◆Steel anilox(Ceramic anilox is optional).

◆Holding slot in the printing cylinder to fix the flexo plate.

◆Computerized gear adjusting for the phase of the printer freely 360° in running and stop.

◆Planetary gear constructure for phase to increase the using times.

◆Brake is installed tp keep the gears fixed when machine units moving.

◆Memorized systerm for the printer.

◆The anilox roll separate automatically from printing plate when sheet is not feeding.

◆Electric element adopts Schneider.

◆Motor adopts reducer moter made in Taiwan.

开槽单元

◆采用单轴双刀结构,后刀采用电动及可电脑设定调整。

◆四刀座均可移动,调整间距采用电动及可电脑设定调整。

◆刀轴与压线轴均表面硬铬并二次精磨。

◆弹性切角刀,三五七层纸板无需调整。

◆手动双向锁调整压轮间隙,调整快速方便。

◆相位固定采用电磁刹车机构,当机台分离或调整相位时保持前刀位置固定。

◆配有触摸显示屏,方便数据设定与控制。

◆可储存订单记忆 999。

◆可电脑全自动排刀。

Slotter Unit

◆Singel-axle double-knives structure is adopted,and the back-knife can be set by computer and adjusted electrically hands.

◆The five-knives set and all be moved,and the adjustment clearance can be set by computer and adjusted electrically by hands.

◆The arbor and pressure line axle both adopt hard twice precision grinding.

◆Thers's the elastic corner-cutting knife.The 3 layers,5 layers and 7 layers cardboard don't need be adjusted.

◆Manual two-ways self-locking used to adjust clamping roller clearance.

◆The phase fixation adopts electromagnetic brake institution.When the machine and stage separate or adjusting the phase,keep the front knife plate fixed.

◆The touch displaying screen is equipped,which makes data setting and control easier.

◆模切辊为优持钢材质,壁厚 40mm,平衡校正,镀硬铬。

◆墙板为优质钢材,壁厚 60mm,大型加工中心制作。

◆软辊自动修磨机构提高胶套重复使用率,可修磨 3 次。

◆线速度自动补偿确保每一批纸箱的模切尺寸完全一致。

◆进口台湾超耐聚胺脂胶垫,安装方便,模切 1200 万次。

◆机械式软辊左右横向移动 40mm,胶垫磨损均匀。

◆六级精磨齿轮采用 40cr 材质,噪音低,使用寿命长。

◆模切辊汽缸式自动分离装置,减少胶套磨损。

Die cutter Unit

◆Die-cutting roller for the high quality steel material,40mm thickness,balance correction,hard-chrome plating.

◆Wallboard for high quality steel material,60mm thickness,and large processing center production.

◆Soft roll grinding mechanism automatically improve glue set of repeated use,can grinding 3-4 times.

◆Line speed automatic compensation to ensure that each batch of carboard boxes in full accord die-size line.

◆Die-cutting rubber is from Taiwan,easy installation,using life of 12 million times.

◆Mechanical soft roll about 40mm lateral movement,the rubber cushion abrasion well-distributed.

◆40cr material is used for gears with 6 degress precision grinding,low noise,long life.

◆Die-cutting roller is used by cylinder style automatic separating device,reduce the wear and tear of rubber pouches.

◆Rotary die-cutting is driven by independent servo motor.

© GuangZhou TaiSheng Carton Machinery Co.,Ltd